Category Archives: Projects and How-To

XP Clutch Cover Removal

Homemade enclosure kit

Thanks in advance!

Homemade enclosure kit

Thanks in advance!

UTVinc 60 AMP Alternator Kit Install Guide (RZR 800)

Okay, I am not the type of person that can be handed 3 pages of instructions containing 26 steps and 10 pictures without trouble. I also will NOT get it done in a "reasonable" amount of time. If a project is usually a 2 hour install, I can count on 3-4 times that….

Box arrives.

I lay out everything, however there is no parts list so I am unaware that I am missing parts (or have the wrong ones until later). The Item with the Red “X” is not part of the o8 RZR 60 AMP Kit, Later this will be replaced with the correct ones and I had to modify a part, deburr another due to shipping damage and buy some washers… No big deal..

Metal on Metal during shipping hurts. Deburred & good to go.

Close up of the remaining “basic” package. Those 3 nuts & bolts needed some washers. Easy fix. See below for the other 2 plates that arrived for the complete kit.

UTVinc Instructions will be written in RED. I will add any notes to help out anyone else.

1. Begin by removing seats, center console and rear firewall.

2. Remove cross bar that seats mount to.

3. Remove stock clutch cover.

4. Using 3” hole saw. Cut a hole as close to center of the nub on the front of the clutch cover.

5. Remove center bolt from clutch assembly. (Ensure that the plastic centering spacer does not get lost)

As much as I am a perfectionist when installing things I felt this might be the most important but was wrong. Yes, center a mark, but being so precise you measure to the millimeter isn’t a deal breaker.

Drill hole

Clean up any loose plastic

NOTE: My 3” Drill bit gave me just a hair under 3” for a hole.

NOTE: When you place the adaptor plate over the hole you will have some “wiggle room”. This is by design. See next pic.

NOTE: Looking on the underside of the adaptor plate. The outside diameter of the inner piece that inserts into the 3” hole is only a bit over 2.5”. Why the difference? You shall see.

This is the layout of the parts that will make-up the Adaptor pulley attached to the outer clutch cover.

This picture is the order of things to be assembled.

In #7 of the instructions it explains that “The pulley must be sitting flush against bearings on cover adaptor.” I tried many different ways of inserting the bearings into the adaptor plate and found it easiest to use my press. I wasn’t comfortable using a mallet although I doubt it would cause harm. The Adaptor and bearing shown are strong. Inserting the pulley was easily done by hand, also when tightening the clutch bolt (later) it ensures good fit.

6. Bolt clutch cover back onto motor using all bolts to ensure correct placement.

This is where I couldn’t figure on the instructions. If I install the pulley (adaptor system) with the clutch cover on and tighten the bolt, how was I going to secure the Clutch from rotating and/or even get it off? So I Went out in town and bought a drainage cap and made a hole so that I could insert a long screwdriver to hold the clutch in place.

7. Assemble pulley and clutch cover adaptor. Pulley must be sitting flush against bearings on cover adaptor. Pulley and bolt must go on as an assembly.

8. Install pulley assembly onto clutch using center bolt.

This is where that “Wiggle room” I mentioned above comes in. If I were to guess I say that all (at least o8 models) will have you install that adaptor plate (Pulley) not center but higher up. The reason being that the clutch cover is not exactly centered over the clutch bolt. It is a very smart design. Take your time lining it up (and marking) when you have tightened the bolt.

9. Using silver sharpie or paint pen mark holes onto stock clutch cover to bolt on clutch adaptor plate.

10. Remove clutch cover again and drill holes using a 5/32 drill bit

Although a 5/32 drill bit will fit through the Aluminum Adaptor housing, I would suggest drilling the holes with an 11/32 drill bit. It is still a tight fit for the screws, but not so tight that you must screw them through.

NOTE: Once the clutch cover is out and the holes marked, it is easier to place the plate back over the marks and use the suggested 5/32 bit and while the plate is secure, drill all the holes. Then remove the plate and use the larger 11/32 drill bit to enlarge the holes just a bit.

11. Bolt clutch cover adaptor onto clutch cover using supplied 8-32 screws with lock-nuts on the outside of the clutch cover.

This is the Adaptor Pulley Assembly from the inside of the clutch cover. The lock-nuts go on the OUTSIDE.

This is the Adaptor Pulley Assembly complete and finally installed in the clutch cover.

NOTE: I was unable to do step 12 without first sliding the clutch bolt assembly through the adaptor pulley FIRST, then angling the bolt into the clutch with the cover ALL together. IF I installed the clutch cover first I was unable to insert the clutch bolt at any angle. I am using a STM Rage III, I do not remember if the bolt is longer.

12. Re-assemble clutch cover onto engine.

13. Re-install clutch center bolt and torque to 40 fl Lbs.

Box #2 Arrives!

Now the 2 proper Alternator mounting plates have arrived. The one shown in the red circle is the one that came in the kit the 1st time. You do not want the one in the red circle.

Very well build main bracket. It just needed a little “trim”.

You can see the “V” cut in the seat bracket mount as well as the top bracket mounting plate. The 3 holes in that plate line up perfectly with the 3 larger holes in the seat bracket as shown.

The issue was when I lined up the lower Alternator bracket that the bracket itself did not have a cut-away for the gear shifter cable.

Alternator plate flipped over.

This shows the basic assembly of the Alternator mounting plates.

Here is a picture of the Alternator plate coming into contact with the gear shift cable. My only concern would be that long term vibrations would cause damage to the cable.

So I used the top piece that came in the kit to make the outline of the piece I wanted cut out and removed the piece, grinded it smooth and painted it to match.

In this picture you can now see all 3 “V’s” Lined up.

14. Install Alternator onto alternator bracket using supplied hardware.

15. Install alternator bracket onto seat frame cross member that was removed during step 2.

16. Re-Install Cross member onto RZR

Next place seat bracket bar with Alternator bracket back in RZR (I recommend) you mount it to ensure that you don’t have any battery/wiring issues that may get in the way. Then pull it back out and mount the Alternator to the Bracket and once again check your clearances. When mounting the Alternator to the Bracket the post marked with a “B” (for Battery) is the upside. Which will have you use the spacer provided with the silver elongated bolt to secure the right “slide” side of the Alternator. The Left and lower bolt connects through the lower left hole on the bracket. Prior to re-installing the assembly into the RZR I recommend you connect the red wire (main Battery POS) to the “B” Post on the top of the Alternator. Then connect the black (ground) to the lower left bolt between the washer and the Alternator as to ground the Alternator housing.

17. Install provided Power cable from the positive battery terminal to terminal post on alternator.

18. Install provided ground cable from negative battery terminal to mounting bolt on alternator to ground housing of alternator.

19. Route alternator switch wire through the floor board and up behind the dash. Using the supplied wire tap and connector, tap into the accessory wire.

20. Install belt and tighten to ¼ inch of play.

21. Re-install Seats and center console

22. This kit is an override of stock charging system (not a replacement).

23. Rear Firewall must be trimmed 14 inches from top in order to fit.

ALTERNATOR Signal Wire Installation

24. Locate the terminal ports on the side of the alternator and connect the signal wire as seen in the picture below.

25. Next route the signal wire to the front of the vehicle using the supplied zip-tyes to secure the signal wire from any moving parts.

26. Locate the orange/white accessory wire located under the dash and connect the signal wire using the supplied connectors.

FINISHED

The Kit is solid. Without a functioning Stator at idle I get a minimum of 11.5-11.7 volts and anything above 2k rpms produces a solid 13volts.

UTVinc 60 AMP Alternator Kit Install Guide (RZR 800)

Okay, I am not the type of person that can be handed 3 pages of instructions containing 26 steps and 10 pictures without trouble. I also will NOT get it done in a "reasonable" amount of time. If a project is usually a 2 hour install, I can count on 3-4 times that….

Box arrives.

I lay out everything, however there is no parts list so I am unaware that I am missing parts (or have the wrong ones until later). The Item with the Red “X” is not part of the o8 RZR 60 AMP Kit, Later this will be replaced with the correct ones and I had to modify a part, deburr another due to shipping damage and buy some washers… No big deal..

Metal on Metal during shipping hurts. Deburred & good to go.

Close up of the remaining “basic” package. Those 3 nuts & bolts needed some washers. Easy fix. See below for the other 2 plates that arrived for the complete kit.

UTVinc Instructions will be written in RED. I will add any notes to help out anyone else.

1. Begin by removing seats, center console and rear firewall.

2. Remove cross bar that seats mount to.

3. Remove stock clutch cover.

4. Using 3” hole saw. Cut a hole as close to center of the nub on the front of the clutch cover.

5. Remove center bolt from clutch assembly. (Ensure that the plastic centering spacer does not get lost)

As much as I am a perfectionist when installing things I felt this might be the most important but was wrong. Yes, center a mark, but being so precise you measure to the millimeter isn’t a deal breaker.

Drill hole

Clean up any loose plastic

NOTE: My 3” Drill bit gave me just a hair under 3” for a hole.

NOTE: When you place the adaptor plate over the hole you will have some “wiggle room”. This is by design. See next pic.

NOTE: Looking on the underside of the adaptor plate. The outside diameter of the inner piece that inserts into the 3” hole is only a bit over 2.5”. Why the difference? You shall see.

This is the layout of the parts that will make-up the Adaptor pulley attached to the outer clutch cover.

This picture is the order of things to be assembled.

In #7 of the instructions it explains that “The pulley must be sitting flush against bearings on cover adaptor.” I tried many different ways of inserting the bearings into the adaptor plate and found it easiest to use my press. I wasn’t comfortable using a mallet although I doubt it would cause harm. The Adaptor and bearing shown are strong. Inserting the pulley was easily done by hand, also when tightening the clutch bolt (later) it ensures good fit.

6. Bolt clutch cover back onto motor using all bolts to ensure correct placement.

This is where I couldn’t figure on the instructions. If I install the pulley (adaptor system) with the clutch cover on and tighten the bolt, how was I going to secure the Clutch from rotating and/or even get it off? So I Went out in town and bought a drainage cap and made a hole so that I could insert a long screwdriver to hold the clutch in place.

7. Assemble pulley and clutch cover adaptor. Pulley must be sitting flush against bearings on cover adaptor. Pulley and bolt must go on as an assembly.

8. Install pulley assembly onto clutch using center bolt.

This is where that “Wiggle room” I mentioned above comes in. If I were to guess I say that all (at least o8 models) will have you install that adaptor plate (Pulley) not center but higher up. The reason being that the clutch cover is not exactly centered over the clutch bolt. It is a very smart design. Take your time lining it up (and marking) when you have tightened the bolt.

9. Using silver sharpie or paint pen mark holes onto stock clutch cover to bolt on clutch adaptor plate.

10. Remove clutch cover again and drill holes using a 5/32 drill bit

Although a 5/32 drill bit will fit through the Aluminum Adaptor housing, I would suggest drilling the holes with an 11/32 drill bit. It is still a tight fit for the screws, but not so tight that you must screw them through.

NOTE: Once the clutch cover is out and the holes marked, it is easier to place the plate back over the marks and use the suggested 5/32 bit and while the plate is secure, drill all the holes. Then remove the plate and use the larger 11/32 drill bit to enlarge the holes just a bit.

11. Bolt clutch cover adaptor onto clutch cover using supplied 8-32 screws with lock-nuts on the outside of the clutch cover.

This is the Adaptor Pulley Assembly from the inside of the clutch cover. The lock-nuts go on the OUTSIDE.

This is the Adaptor Pulley Assembly complete and finally installed in the clutch cover.

NOTE: I was unable to do step 12 without first sliding the clutch bolt assembly through the adaptor pulley FIRST, then angling the bolt into the clutch with the cover ALL together. IF I installed the clutch cover first I was unable to insert the clutch bolt at any angle. I am using a STM Rage III, I do not remember if the bolt is longer.

12. Re-assemble clutch cover onto engine.

13. Re-install clutch center bolt and torque to 40 fl Lbs.

Box #2 Arrives!

Now the 2 proper Alternator mounting plates have arrived. The one shown in the red circle is the one that came in the kit the 1st time. You do not want the one in the red circle.

Very well build main bracket. It just needed a little “trim”.

You can see the “V” cut in the seat bracket mount as well as the top bracket mounting plate. The 3 holes in that plate line up perfectly with the 3 larger holes in the seat bracket as shown.

The issue was when I lined up the lower Alternator bracket that the bracket itself did not have a cut-away for the gear shifter cable.

Alternator plate flipped over.

This shows the basic assembly of the Alternator mounting plates.

Here is a picture of the Alternator plate coming into contact with the gear shift cable. My only concern would be that long term vibrations would cause damage to the cable.

So I used the top piece that came in the kit to make the outline of the piece I wanted cut out and removed the piece, grinded it smooth and painted it to match.

In this picture you can now see all 3 “V’s” Lined up.

14. Install Alternator onto alternator bracket using supplied hardware.

15. Install alternator bracket onto seat frame cross member that was removed during step 2.

16. Re-Install Cross member onto RZR

Next place seat bracket bar with Alternator bracket back in RZR (I recommend) you mount it to ensure that you don’t have any battery/wiring issues that may get in the way. Then pull it back out and mount the Alternator to the Bracket and once again check your clearances. When mounting the Alternator to the Bracket the post marked with a “B” (for Battery) is the upside. Which will have you use the spacer provided with the silver elongated bolt to secure the right “slide” side of the Alternator. The Left and lower bolt connects through the lower left hole on the bracket. Prior to re-installing the assembly into the RZR I recommend you connect the red wire (main Battery POS) to the “B” Post on the top of the Alternator. Then connect the black (ground) to the lower left bolt between the washer and the Alternator as to ground the Alternator housing.

17. Install provided Power cable from the positive battery terminal to terminal post on alternator.

18. Install provided ground cable from negative battery terminal to mounting bolt on alternator to ground housing of alternator.

19. Route alternator switch wire through the floor board and up behind the dash. Using the supplied wire tap and connector, tap into the accessory wire.

20. Install belt and tighten to ¼ inch of play.

21. Re-install Seats and center console

22. This kit is an override of stock charging system (not a replacement).

23. Rear Firewall must be trimmed 14 inches from top in order to fit.

ALTERNATOR Signal Wire Installation

24. Locate the terminal ports on the side of the alternator and connect the signal wire as seen in the picture below.

25. Next route the signal wire to the front of the vehicle using the supplied zip-tyes to secure the signal wire from any moving parts.

26. Locate the orange/white accessory wire located under the dash and connect the signal wire using the supplied connectors.

FINISHED

The Kit is solid. Without a functioning Stator at idle I get a minimum of 11.5-11.7 volts and anything above 2k rpms produces a solid 13volts.

2015 900S front tow ring with Polaris bumper

While I was installing the new Super Dave bushing kit I decided to install the new winch while I was there. I took the front grille off for easier access. The front bumper had to also be removed because the fair lead plate goes behind it. I started thinking about a front tow hook or "D" ring but with the Polaris front bumper, there are not many options. As most of my projects begin by making conceptual sketches to eliminate the possibilities that won’t work I came up with this. I used a large "D" ring which fits between the lower tubes on the bumper and bolted it thru the bumper holes. I attached the sketches if you want to build one. If you use the sketches and photos, it will not be hard to determine the dimensions starting with the "D" ring. Note that the top of the angle iron is notched on each side so the "D" ring can swing up past horizontal. Be careful when laying out the ring and bolt holes that it does not extend below the bottom of the vehicle. I am going to use it to attach the winch hook to when I get done with the installation. So take your time and have fun, that’s what it’s all about! :ok:

Shock Nitrogen Charge Service

Just a quick "How To" on Nitrogen Charge Service.

Here’s how its done;

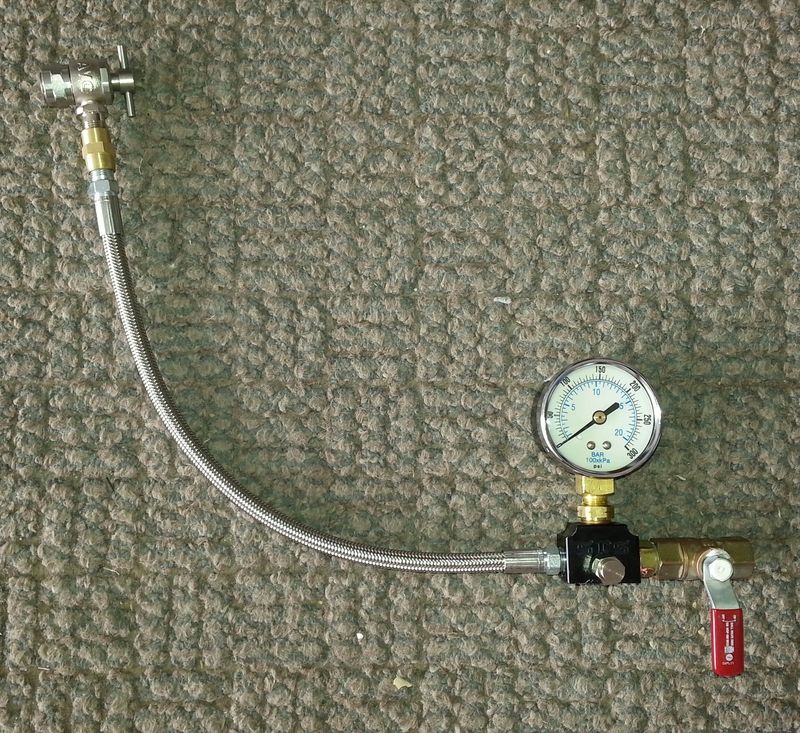

You’ll need a zero loss nitrogen fill tool,

Got mine on ebay $85,

Note the manual valve I installed,

I like to control the pressure from the regulator

to the shock.

You’ll also need a nitrogen bottle and a regulator.

This is my setup.

Bleed out the regulator hose and fill tool and connect to the shock reservoir.

Set regulator to 125 psi,

Make sure the manual valve is closed,

Screw in Schrader T-valve until you have a reading on the fill tool gauge.

My left front read 80 psi.

Slowly open the manual valve until the fill tool gauge reads 125 psi,

You now have 125 psi in the shock reservoir,

Close the manual valve and unscrew the Schrader T-valve.

You have now serviced your shock reservoir to 125 psi.

Repeat on all four shocks.

This is my setup hooked to the right rear,

These were my reading at 1650 miles;

Left Front………….80 psi

Right front…………80 psi

Left rear…………..110 psi

Right rear…………100 psi

I serviced al four shocks to 125 psi.